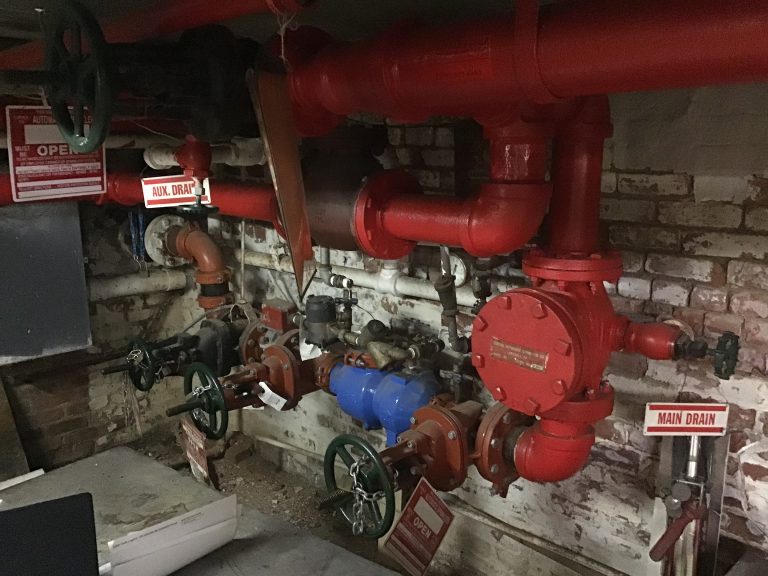

Backflow Prevention in Commercial Fire Sprinkler Systems & Compliance in NYC

Ensuring Safe Water and Compliance: Testing, Troubleshooting, and Repairing Backflow Assemblies in Commercial Fire Protection Systems

No restaurant owner or property manager wants to gamble with FDNY inspections, fire safety violations, or system failures — and that’s why so many NYC businesses rely on Master Fire Mechanical, the trusted fire protection and commercial kitchen fire safety specialists serving New York City from Yonkers to the East Village, and Midtown to Gravesend as well as many other great New York City eating locals including Harlem, Washington Heights.

We understand how stressful it can be to deal with failed inspections, violation notices, emergency shutdowns, and aging fire protection systems — especially when your business, staff, and customers are on the line. Our team works directly with restaurant owners, building managers, and contractors to correct issues quickly, document compliance properly, and keep systems operating safely.

From our Bronx-based operations, Master Fire Mechanical proudly serves all five NYC boroughs — including Manhattan, Brooklyn, Queens, The Bronx, and Staten Island — providing fire suppression systems, hood & duct protection, exhaust system support, sprinkler coordination, inspections, testing, maintenance, and violations removal.

Whether you’re opening a new restaurant, upgrading an existing commercial kitchen, responding to a failed FDNY inspection, or taking over a previously closed space, Master Fire Mechanical is here to protect your operation and keep you compliant.

Stay informed and inspection-ready:

Subscribe to our YouTube channel for short, practical fire safety videos, read our Blog (updated weekly with real NYC field insights), and follow us on Instagram for behind-the-scenes service work and compliance tips.